Poul Willumsen has made an international name for itself with its colourful piggy banks and key pendants. The family business has been producing plastic products per injection moulding in Farum, North of Copenhagen for more than 50 years.

“Denmark always was and always will be our production location – we have good reasons for that,” stated Willumsen. The CEO and owner of Poul Willumsen has been successfully demonstrating for decades that one can also survive on the price-conscious haptic advertising market with products “made in Denmark“. The colourful plastic creations of the company from Farum in Zealand – primarily the piggy banks – are wellknown throughout the industry and promotional products distributors all over Europe appreciate the high-quality products, service and reliability of the 20-man team of the family business. “Our biggest competitive edge compared to our rival companies from the Far East is our quality, short delivery times and design,” reported Willumsen, who runs the company together with his wife Christa. It was thanks to his initiative that the company, which was founded by his father Poul in the 1950s, became involved with promotional products: “Originally we supplied the industry with plastic parts. When I started working for the company we were almost bankrupt. I said to my father, if we wanted to earn anything we would have to develop and sell our own products. We already had a piggy bank among our collection at the time. So, we started designing piggy banks. The promotional products market was the target group. In 1981, I newly founded the company.”

Willumsen hired an industrial designer and together more and more designs were developed as well as the corresponding tools. “One of our first big orders was a bespoke design for a customer who wanted a savings box with a Tintin motif. We produced this here in Denmark and painted it using a spray gun. That gave us the idea for an own product – a coin sorter,” recalled Willumsen. “Up until this very day our products are all our own collecdesigns and they are correspondingly patented.” The line-up has gradually grown over the years and today includes over 30 different piggy banks and approx. 40 key pendants, enhanced by further items such as coin sorters and card holders. “Some of our products are very elaborate to manufacture,” explained Willumsen. “For the filigree ears of some of the models of piggy banks, one needs several different injection moulds, the individual elements of which have to fit together perfectly during the injection moulding process.” In the course of decades of experience and everyday practice in the plastic production market, new ideas sometimes even arise by coincidence, as Willumsen reported: “We offer some of our key pendants as an execution with air pockets – this originally came about due to an error in the hardening process that occurred once, which we subsequently ‘systemised’ to achieve an attractive visual effect.”

F.t.l.: Bo Willumsen (CEO and owner), Christa Willumsen (Sales Manager), Kim von Wowern (Sales Director) and Anne Marie Gilling (Marketing & Sales Coordinator).

All products are available in 14 standard full colours and 13 transparent shades as well as in two different metallic or silk-matt and three pearl finishes. “For specific minimum order quantities we also realise special Pantone colours and totally specialised designs that each have their own injection mould,” the Sales Director, Kim von Wowern, stated. “If the customer only wants to implement a specially shaped product in a certain printmarket and we can sell this product in other markets, we pay for part of the tool costs.”

Streamlined production

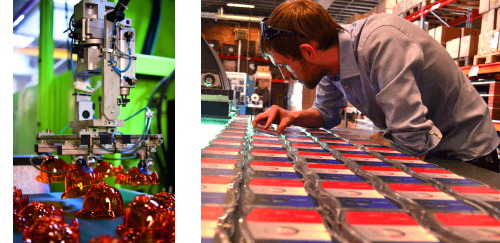

Apart from the tool making, all work steps are carried out on-site in Farum. “Because we manufacture here in Europe, we can produce on time and don’t have to stock huge volumes,” Willumsen explained. “The production on demand is in line with the general trend towards smaller, but more frequent order volumes. In spite of orderrelated production, we can deliver fast because the routes are short and the processes are efficient. Instead of warehousing, we prefer to invest in production machines.” Modern injection moulding machines guarantee a high throughput. For the piggy banks, two halves are cast first of all, these are then welded together by ultrasound. “We need an own sonotrode for each model,” explained Willumsen. “The machine is highly-sensitive – if exposed to just one shock it could break.” In terms of customising methods, Poul Willumsen relies on pad and in particular digital printing, “for me the meanwhile most attractive printing technique, because it provides a brilliant, razor-sharp print ing result without set-up costs and within short lead-times,” commented Willumsen.

// Till Barth

photos: Till Barth, © WA Media (1); Poul Willumsen (3)