Small volumes and short delivery times – that is what digital print-on-demand promises. Personalisation is possible per mouse click, whole designs can be self-created. This not only has an effect on the products, it also enables the promotional products industry to reach the big group of small users.

Since easily connecting the book trade with the digital printer has become reality, it has been possible to first print a book once an interested reader has really been found. This production – called book-on-demand – has its advantages: There are no advance printing costs, no warehousing costs for too optimistically planned circulations, fast processing and swift production. What is long since no longer just a trend in the book segment, but which has indeed meanwhile turned into a whole sector, is having an increasingly significant effect on the promotional products market, the principle here is referred to as print-on-demand. Thanks to digital printing, small delivery volumes can be produced in a cost-efficient manner and the lead-times become hugely reduced, since only one file is needed for the print preparation. The logistic advantages of print-on-demand lead to direct effects on the printed products themselves too. Intuitively designed websites and the widely used Internet in combination with the new printing technologies, make the so-called mass customisation of promotional products possible too – a mixture between mass production and individual manufacture, which unites the benefits of both types of production, namely efficient processes and individual specifications. For the industry this opens up new paths for innovative and above all more individual products and they will be in even higher demand in the future, according to Christoph Ruhrmann, one of the Managing Directors of the full-service agency, Plan Concept: “The end customer expects more individuality and this is also having an impact on the promotional products industry.”

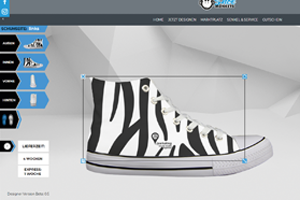

Self-made shoe designs

Without this trend the company Scurdy probably wouldn’t exist in its present form. The Scurdy CEO Manuel Langele and his team have already been producing personalised sneakers since 2011, after the take-over by Kumaco in the year 2017 under the label Shoe Monkeys and using a newly programmed online configurator. Customers can create the design of the shoes themselves on the company’s website. This is exciting for those consumers, who are seeking to express their individuality and is thus especially interesting for promotional products users.

“Around ten years ago we saw self-designed sneakers in the USA,” said Langele adding: “There wasn’t anything like it in Germany we found the theme fascinating and wanted to put it into practice.” Langele got to work with his co-founder Max von Papen and had own Scurdy sneakers produced. However, personalising them proved to be an elaborate process: In collaboration with other companies Scurdy initially had fabric imprinted in line with the specifications of the individual designs, the individual parts of the shoe were then made out of the material and everything was sewn together. So, essentially every shoe was a unique specimen and the whole thing was correspondingly time-consuming and expensive too. Nevertheless, this changed once the digital printing technology made further progress, because all of a sudden one could imprint fabric shoes like T-shirts – in other words the complete already finished shoe. “In 2014, we saw and realised immediately that this of course also meant a huge reduction of the costs and an enormous amount of saved time,” Langele explained the advantages. It wasn’t until then that the idea of allowing the customer to design sneakers himself online, could be viably realised. The website of Shoe Monkeys was subsequently launched after the take-over by Kumaco in the year 2017.

The configurator is the centrepiece of the website. It places various design tools at the disposal of the customer allowing him to start designing straight away without any previous graphic knowledge being necessary; however it is also possible to directly upload own designs that have already been produced. The shoes are then imprinted at the production site using specially developed digital printing machines: The shoe is spanned over a plate, a camera takes a screenshot of the shoe. The graphic designer then sees the uploaded design on the shoe on his monitor. If everything looks right, it is printed; next the shoe takes a ride on the drying belt and depending on how many sides of the shoe are to be imprinted, the same procedure occurs several times. Five printing machines work in this way. Depending on how elaborate the designs are, sometimes 50, sometimes 500 shoes come off the conveyor belt at the end of the day and are delivered to the customers’ homes.

The sneakers are already implemented as advertising messengers, as the CEO stated: “IBM for instance is one of our customers – at the Dmexco show the IBM employees wore sneakers in the company’s corporate design that were produced by us.” However, establishing the contact took place following a more classic method: “They found us online and simply called us.” Scurdy currently offers promotional products distributors and consultants the opportunity to design sneakers for their customers online, download the finished design on a plain background and present it to the customers for approval. This is an interim solution, reported Langele, until a real white label shop can be set up.

B2B learns from B2C

The institutionalised form of printing on demand in such white label shops is called web-to-print. One configures the desired promotional product online, clicks on order, a print file is then sent to the digital printer by the distributor or the manufacturer and this then delivers the product with the desired individualisation in the required quantity. Individualisations and personalisations are so favourably-priced thanks to digital printing and shortened approval procedures that even just one single item can be delivered in an uncomplicated process. This is already the order of the day in the merchandising segment. For example, fan shops more and more frequently offer personalisable fan items online. Plan Concept is responsible for the personalisable products – with the exception of the kits – of the online fan shops of several football clubs, including the online shop of Borussia Dortmund.

“There among others we offer lunchboxes and mobile phone cases that can be personalised and ordered in a few clicks,” said Ruhrmann and explained the principle: “The design of the lunchboxes or mobile phone case is already posted in a file. The customer simply just changes the desired name via the webshop and the finished print file goes directly to our digital printing machines. Through to the packing process the lunchbox is not touched by one single person.” What is already the everyday routine in the B2C sector, is now starting to effect classic B2B products like promotional products. Ruhrmann: “We, the B2B industry have to learn from B2C, for instance we have to work more intuitively. What does the customer enjoy doing? What puts him off, where does he break off the ordering process without having submitted an order? How can we also offer the B2B customer what he is already familiar with from the B2C sector?” And Ruhrmann also explained that the customer is from his private consumption habits already used to being able to order relatively simple products online relatively fast and simply per mouse click and that these products are delivered within a short space of time. Web-to-print shops for promotional products are the industry’s answer to this development.

Plan Concept is one of the pioneers of the print-on-demand principle in the promotional products business. “First of all we only used the technology to produce favourably-priced samples – after all the haptic feel plays a key role with promotional products,” explained Ruhrmann: “But we soon noticed that there is a market for print-on-demand products.” In addition to reducing the warehouse stocks, print-ondemand also makes co-branding easier and thus extends the spectrum of services of the promotional products distributors and manufacturers. However, all of this only works if the processes themselves are digital and thus to a large extent automated,” noted Ruhrmann. In this way sources of errors can be avoided: “The more people involved in the ordering process, the more errors can occur.” Hence, digitalisation in the printing area doesn’t merely comprise of a digital printing machine in the centre of a hall, but is indeed the optimisation of all processes with the aim of printing items in a way that is as resource-friendly as possible.

New paths to smaller customers

At the sweets specialists, Kalfany Süße Werbung, one has made the experience that printon-demand enables the distributors to access the market of small and tiny users. Since 2016 the distributors have the opportunity to order relatively low volume orders of Kalfany products with individualised packaging via a closed shop that is only accessible via a log-in. The individualisation of the packaging per online editor is already possible for ten products available all year and two advent calendars that are only offered seasonally for obvious reasons, further parts of the line-up are to be added to the list. Kalfany offers this service for the top-sellers, which alongside fruit gums are also wrapped sweets and chocolate.

“The user has more individual responsibility for the product, but it is also more autonomous as a result,” said Stefan Eiche, Deputy Sales Director at Kalfany. The editor gives the customer the opportunity to upload own photos or completely design the packaging himself – apart from the legally binding details, such as the nutritional content and sell-by dates. In a 3D preview the user can examine his draft again before finalising the ordering process and before a print file is generated. “The current version of the editor also warns the user if the image quality isn’t optimal and we receive an alert ourselves if any possibly illegal material is uploaded,” Eiche’s colleague, Florian Meier, said, explaining some of the functions. Meier has been Project Manager of the Business 4.0 department since the beginning of 2019 and is thus Kalfany’s digital expert. “We have copied quite a few things from the printing industry and automated as much as possible including the data checks,” is how he summarised the new processes.

At the sweets specialists Kalfany Süße Werbung distributors can design selected products individually according to their customers’ requirements using an online editor.

This is especially an advantage when the margins are fairly low. Both experts say that Kalfany’s web-to-print solution is thus primarily suitable for smaller campaigns. “Here the distributors have to decide: Who are my customers?” said Eiche and elucidated: “I wouldn’t tend to realise the campaign for Daimler’s new E-Class with a few clicks online, but instead organise it offline in the classic way in close cooperation with their sales department. But web-to-print is ideal for little bars of chocolate for the café over the road or for the sachets of fruit gums for the garage next door, because it also makes promotional products accessible to smaller and tiny volume users.“ Pretty much in the wake of the webshop, Kalfany is integrating more and more digital gimmicks in the workflows. For instance the usability of the webshops is under constant development and since recently text fields explain the symbols of the editor and several technical terms. And anyone who simply calls up Kalfany Süße Werbung’s website, will after a few moments be asked in a small chat window, whether they perhaps need any assistance. And according to Eiche and Meier unanimously, the customers appreciate these small digital services.

New competitors

Screen print production at Flyeralarm: The online printing company also wants to set new standard delivery times and to this end is relying on the Disperse Master DM4 of Wilflex, which allows customer-specific pantone colours to be mixed fully-automatically.

So in the light of all this it is not surprising that online printing companies like Vistaprint or Flyeralarm are starting to operate on the promotional products market that is actually characterised by customer contacts: “For us as an ecommerce company, the whole thing is quite clearly an exciting challenge to more or less combine online sales with offline consulting,” remarked Pascal Ritter, head of the newly founded division, Flyeralarm Give Aways. Flyeralarm now offers promotional products and services related to give-aways via a website that was launched at the end of 2018. “We work in a similar way to other promotional products distributors,” said Ritter. According to him the online printing company has from the very beginning distinguished itself from the others in its digital approach: “For example, we continually work on optimising our homepage for search machines so that we stand high up in the ranking by Google for certain keywords, which means that we are normally among the top hits at present,” commented Ritter. Flyeralarm intends to stand out from the masses of competitors with short delivery times because that is what the big clientele is used to. Overnight delivery is possible for several items from the bags and textiles area that are even customised with a screen print, Ritter noted and said that this option is to be extended to include further items during the course of 2019. This is made possible by Wilflex’s DispenseMaster DM4. According to Flyeralarm, it is the only printing company in Germany that owns the machine which can mix customer-specific colours almost fully-automatically. “Our aim is to reduce the standard delivery times in the promotional products business,” announced Ritter.

But even if Flyeralarm is already working on the solutions that will even allow orders of promotional products to be printed using augmented reality options, Ritter is convinced: “The right mixture between digital possibilities and analogue contact will always remain important in this industry.” The outcome: Not every customer contact will simply be digitalised away. Special designs still require a personal exchange and some individualising techniques simply can’t be digitalised without risking that the required parrot ends up looking more like a racoon. “Print-on-demand will become standard within the industry,” the industry expert Ruhrmann is however convinced and added: “Those companies that don’t take the digitalisation seriously, will be out on a limb.”

// Klara Walk

Photos: BVB Merchandising (2); Flyeralarm (1); Kalfany Süße Werbung (1); Scurdy (3)