Pagani Pens has been setting trends and standards on the international market for 60 years with “made in Switzerland” writing instruments and writing instrument components. Billions of refills are still sold all over the world today under the brand name Premec, whilst the brand Prodir constantly reinvents itself in line with what is possible in the areas of design, materials and functionality. Beyond this the company from Ticino follows a coherent and far-reaching sustainability policy that is also reflected by exciting product innovations and builds a bridge to the digital world with its Cloud Pens.

“But it is just a pen.” The sales team of Prodir hears this sentence again and again when it comes down to the prices. However, to put the statement “just a pen” into context, one simply has to pick the item up and examine it carefully: Anyone, who is a little bit familiar with the promotion market, sees and feels the difference between a Prodir writing instrument and products from the low-priced segment – and companies that select Prodir products as ambassadors for their brand, bet on the highest quality in design and production, namely on “Personality Pens. Swiss made”. Pagani Pens celebrated two anniversaries last year: Prodir was founded 40 years ago and Premec was established 60 years ago. In 1961, on founding Premec, Giorgio Pagani, who is still today President of the Administrative Board, laid the foundation for today’s corporate group, which currently employs a headcount of 420 people. Strong growth contributed towards the two companies, Prodir and Premec, merging in 2017 to form the newly-found company, Pagani Pens SA. In 2018, the fusion was completed by splitting the company up into the business units “Components” and “Writing Instruments”.

At the start Premec completely concentrated on the tips for the ballpoint pens that were quite new back then. In 2008 the company expanded the production to include inks and since 2002 they have also been manufacturing refills. Within a few years Premec became a leading international manufacturer of components for writing systems. Up to eight billion tips for practically every writing system were produced annually for customers all over the globe. “Up to this very day Premec has sold over 100 billion tips in total – one can say that every person on this planet has probably written with a pen that contains Premec components at least once,” explained Dr. Eckhard Sohns, Chief Sales & Marketing Officer. “Premec still focuses on global markets both from a sales and development point of view.” This is reflected for example by exciting innovations such as the Anti Fiber Intake Tip – AFIT for short: “In many regions of the world, the paper used is of poorer quality than that implemented in the rich industry states,” explained Rossanna Porotti, who, like Sohns, in her function as COO is a member of the extended executive board. “Among others this leads to the fact that after a relatively short period of time the ballpoint pens used don’t write clearly or even become totally blocked, because paper fibres get stuck between the ball and tip. Thanks to AFIT this doesn’t happen anymore. This significantly extends the service life of a refill. That is better for the people and the environment.”

The Premec components particularly set sustainable accents, for example with the established Floating Ball® refill, which combines a lead-free nib made of stainless steel and a lowpollutant ink. The one thing all Premec refills have in common is their long writing capacity – in the case of large-capacity refills this is around 5,000 m. Laura Bazzali, Product Manager Pens at Prodir, calculated how long the refills last: “Someone, who writes two metres a day, can make notes for five years before the refill has to be changed – which is a simple process. Prodir is the first manufacturer on the haptic advertising market that exclusively offers refillable writing instruments.”

Award-winning designs

Founded in 1981, today Prodir sells writing instruments worldwide via its seven subsidiaries, the main focus lies on Europe. Since 1994 the brand has been concentrating on the haptic advertising market – a good decision as Sohns stressed: “We like being part of this market because it offers the perfect environment for our design and quality claim. Communications and the product are perfectly interlinked on the promotion market. That is what makes it so exciting and unique.”

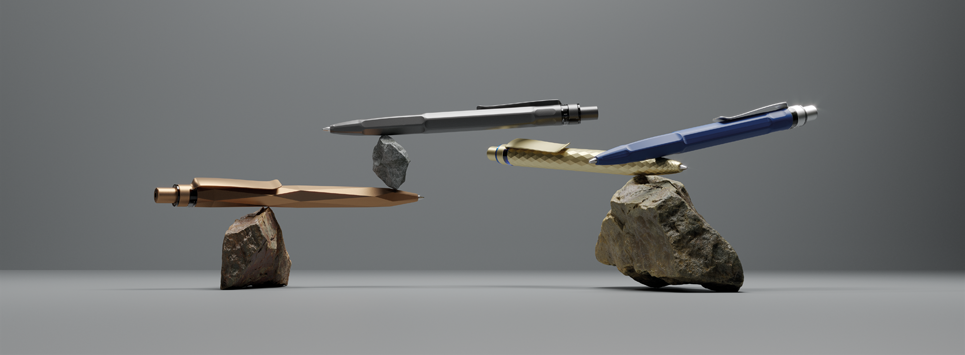

And Prodir has been demonstrating for decades how one can combine communicative potential with exciting shapes and perfect functionality in new ways again and again. Whether timeless classics like the icon DS3, whether the DS2 with its unique pusher or the DS8 with its striking triangular shape, whether the exciting polygonal surface structure of the QS series or unusual colours and finishes: Prodir’s writing instrument creations, which have been designed by the Milan-based Studio C of the designer Christoph Schnug for years, keep on setting new trends and have won many international awards – among others the Promotional Gift Award, the iF Product Design Award and the Good Design Award.

Vertical integration

The writing instruments are assembled and finished at the Pagani Pens headquarters in Lamone.

In addition to the administration, sales and management, also the assembly and customising shop for pad and screen printing are located at the headquarters of Pagani Pens in Lamone, not far from Lugano in the Italian-speaking Swiss canton Ticino. Premec produces and develops tips, inks and refills in Cadempino and the barrels for the writing instruments are finally made in Novazzano: This is not only where the plastic parts are dye cast, the injection moulds are also developed, produced and serviced there. “That we carry all of the production steps out under one roof, is an elementary factor for our success,” explained Porotti. “The fact that we build our own moulds means we can keep on creating new designs and react quickly. On top of that we also offer fast delivery times: In the scope of our ‘Fastlane’ service we can deliver order quantities of between 500 and 5,000 pieces with an up to four-colour imprint on the clip within five working days. Not to forget the diverse individualising options that are possible for all models.”

Each single writing instrument is available in a wide range of colours, combinations and executions, the material of the clip and the type of refill can be freely chosen in the case of many models. The configurator on the Prodir website offers an overview of the options. Furthermore, for a certain order volume upwards special colours can be realised. “Here too we offer much more than “just ballpoint pens,” grinned Maurizio Peverelli, Sales Director for Switzerland at Pagani Pens. Samples of all custom-made items are kept to guarantee absolute colour fidelity in the case of follow-up orders. A strict quality management ensures that no defective writing instrument leaves the production line. Sohns: “We like using the Italian word ‘pignolo’, the closest translation of which is perhaps ‘meticulous’ – that hits the nail pretty much on the head.”

The R&D department of Prodir is also based in Novazzano, which constantly experiments with new, unusual forms, materials and colours together with product designers. Anyone, who thinks the Corona crisis has put the dampers on the innovative power of the Ticino-based company, is mistaken: “In 2018, we established an innovation team where employees from the production, sales, development, product management, executive board and external consultants and designers such as Christoph Schnug from Studio C work together on new solutions in a structured way. Thanks to our high level of vertical integration we can test and implement all ideas fast,” stated Sohns. “The crisis has clearly confirmed the importance of our high investments in research and development. The demand for innovations that deliver strong added value for the communications side has increased significantly over the past two years. This too has helped us weather the crisis well.”

Stone, shell limestone and bacteria

Fascinating surface texture meets noble metal clip: The DS5 Shell Metal Clip contains recycled shells.

Sustainability plays a major role in many of the latest and current developments. Among others the QS40 Air that was presented in 2019 caused a stir with its finely perforated honeycomb structure that grants a view of the interior of the writing instrument. 60% less plastic is required to produce the pleasantly light-weighted ballpoint pen thanks to the perforated barrel, 50% of which comprises of recycled plastic. Much less plastic, half of which is recycled, is also implemented for the material innovations Stone and Shell: Here part of the plastic granulate is replaced by minerals or recycled shells – to produce a writing instrument with a fascinating surface texture, which is heavier and lends the pen its noble appearance. Three models of the QS series are currently available as Stone versions, whilst the new DS5 Metal Clip is available as a shell execution with a natural surface.

However, the most spectacular material innovation is without doubt the bioplastic material, PHA, which Prodir introduced in 2021 under the name True Biotic: PHA – short for polyhydroxyalkanoate – is made from microorganisms through natural biosynthesis. Unlike other “organic” plastics the material is free of residues and completely biodegradable – in soil, salt and fresh water. The carbon cycle remains closed and the whole material is transformed without anything getting lost. At the moment, both the QS40 Air and most recently the DS8 are available as True Biotic models. “We can only realise such innovations, because we are 100% responsible for both the mould making and the injection moulding,” underlined Porotti. “For example, the body of the QS40 Air took many attempts because it was very difficult to produce. Giorgio Pagani himself said at the start that it was impossible to make this mould – but our employees didn’t give up and finally they succeeded in achieving their aim, first of all using ABS and then also with PHA. This requires not only decades of experience, but also a good dose of passion.”

Last, but not least since the beginning of 2022, all writing instruments that are totally or partly made from ABS carry the triangular recycling logo. Bazzali explained the concept behind this: “All coloured models now comprise of 50% recycled plastic, the black and white models are even made from 100% recycled material, which either originates from our own production or from nearby European sources.” “However, our sustainability efforts go much further than the actual writing instruments,” added Porotti. “For example, our production and administration is 100% powered by Swiss hydroelectric power stations.”

First-class communications

Pagani Pens has documented its commitment in the field of sustainability in its own sustainability report. The brochure was drafted and designed by a player from the region – the Studio CCRZ. The architects and graphic design office located in nearby Balerna is also responsible for Prodir’s printed materials and exhibition appearances and develops the packaging and presentation concepts which Prodir has won international prizes for such as the Red Dot Award and which always attract the attention of its trading partners. “Our writing instruments are communication tools, they have to do this job well, that is what they are paid for so to speak,” reported Sohns. “Hence, we don’t consider good communications to be a luxury, it is particularly important for the credibility of our central value promise. This understanding was always key for the brand Prodir. CCRZ carries on this tradition.” This leads to great developments such as the packaging made from corrugated cardboard and recycling materials inside which Prodir recently delivered its sustainable writing instrument innovations onto the market. “Since many trade shows weren’t able to take place,” continued Sohns, “we invested what we have saved in marketing budget during the Corona crisis into mailing campaigns for instance, which we used to inform our partners in a very high-class manner.” The customer magazine open:, which appears twice a year, is also designed by CCRZ. Sohns: “We love print and will never do away with communicating using analogue tools. That is part of our DNA. Whereby today our catalogues and product information only appear in digital format – a print medium simply can’t reflect the diversity and depth of our portfolio adequately. Where it is expedient we are consistently tackling digitalisation.”

High-quality communication concepts are created in cooperation with the design studio CCRZ.

From a clip in the Cloud

This also applies to the products: Prodir has been building a bridge to the digital world with the Cloud Pens since 2021 by offering the opportunity to link up its writing instruments with landing pages using QR codes imprinted on them, which the users can equip, completely individualise, track and manage using many different functions. “The special thing about the Cloud Pens is not the QR code, we have only chosen this as the interface, because it is well-known, easily scannable and environmentally-friendly in comparison to NFC chips for instance,” stated Peverelli. “Their hallmark is far more the digital infrastructure they conceal: The landing page cannot only be completely designed to match the CI, a host of elements and functions can be inserted – photos, contact data, links, videos, call-to-action buttons and much more. Companies can address the users of their brand ambassadors with digital offers directly and repeatedly. Thanks to precise analysis data, the performance of a campaign can be measured, if required updated and adapted at any time. The handling is so simple and intuitive that one doesn’t need any prior knowledge at all – and the best thing is: From February 2022 onwards, we will be offering the basic version as a freemium – i.e. completely free of charge.”

Whether fashion companies, who want to lead their target group to their online shop or social media channels, whether a pizza service that integrates a menu with an ordering function or an insurance company that is looking for an attention-grabbing alternative to a business card – the possibilities are unlimited. The touchpoint in the truest sense of the word remains to be a haptic promotional product – a writing instrument in this case. But one that is far more than “just a pen”.

// Till Barth

www.paganipens.com

www.prodir.com

Photos: Pagani Pens