Under the new proprietor and CEO, Daniel Jeschonowski, Senator is focusing on simplicity and reliability. Thanks to a strict implementation of the corporate philosophy and a stringent brand image, the writing instrument and mug specialist has succeeded in turning the company around and finding its way back to its old strengths.

It is often details that reveal a lot about the state of a company. One such detail is the display above the main entrance to Senator’s headquarters in Groß-Bieberau: It reads “We have had no accidents for 305 days” (status on: March 6, 2018). Daniel Jeschonowski, CEO of the traditional writing instrument manufacturer and porcelain embellisher since July 8, 2016, had the display installed and is visibly delighted that the safety provisions in the factory are obviously being taken seriously. “Many people consider such a display to be superfluous, but it documents the fact that we don’t measure our company’s success by the sales figures alone, but indeed actually take a holistic view of things including such measures.”

Fresh momentum

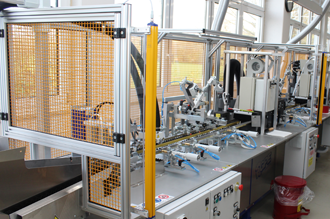

Since Jeschonowski has been in office, he has placed great importance on setting clear rules that are abided to within the company. This includes both a clear and solid price policy as well as sticking to the production targets in the machine park. Whether for the assembly or printing of the writing instruments – tidiness and cleanliness dominate the picture, one could literally eat from the floor. And if a shred of paper does happen to be lying around the boss of the company doesn’t hesitate to pick it up himself. Unpretentious, but dedicated to his management style, Jeschonowski has blown a new wind into Senator’s sails within a short space of time. “This is my baby,” he said proudly and emanates an enthusiasm that is infectious and which has triggered off new impetus. This is tangible in all sections, from the marketing department to the sales, through to the customising and picking and packing divisions.

A sign of the upward turn: On the notice board, where among others the job offers are posted, one can read that that there are vacancies for apprentices and skilled workers in almost all areas. Some vacancies aren’t easy to fill, but that is a luxury problem. It wasn’t long ago that Senator had totally different personnel problems to deal with. In May 2016, the long-standing Senator owner Merz sold the promotional products giant to the internationally-operating private equity company, Perusa. Jeschonowski, who began his career as a consultant and earned many merits as a troubleshooter (among others for Airbus) with a clear focus on sales and production, encountered a company in extreme difficulties when he joined Senator in the summer of 2016. The company was in the red every month, the costs outweighed the revenue by far. The then 35-year-old had no other choice than to take drastic measures and dismiss personnel. Senator had to let around one fifth of the approx. 400 employees go.

Not an easy start for the man from Hamburg, but anyone who thinks the workforce resent him for this and haven’t got a good word to say about him, is mistaken. The mood of the team is relaxed and optimistic due to the new perspective that is arising. “Everyone is pulling together,” said Jeschonowski happily. He knows that a business the size of Senator is carried by the employees. This is also underlined by a page in the new catalogue, which shows the portraits of all of the team members. “More Senator – more you” – the company’s slogan not only applies to the customising options for the promoting brands, but also to the fact that every individual person contributes towards the overall success.

CEO Daniel Jeschonowski together with Anke Niebel, Marketing & Communication Manager.

Reliability

In this respect Jeschonowski is not only orienting himself on successful medium-sized companies for the realignment of Senator. “We are a production company and as such we have to keep our eyes on the production processes. For me it is for instance extremely important that we fulfil the targets regarding the volumes and delivery dates with each individual machine.” Reliability – both internally and externally – is becoming the new credo. “In the past there were many experiments that led to the customers no longer knowing what Senator stands for,” stated Jeschonowski. He doesn’t want this to happen under his aegis. “We want to re-position ourselves as a reliable partner of the promotional products trade.” In addition to delivering on time this also includes a lower rate of complaints and a totally solid price policy. “We don’t play along with the price campaigns,” stressed Jeschonowski, who has instructed his sales department to turn down orders if they don’t attain the set margins from a financial point of view. The industry price list for 2018 has been laid down, the prices are not to be changed in the course of the year come what may.

This new clarity is going down well. “An air of tranquility has returned. We have taken up our place within the industry again and the figures are right,” confirmed Jeschonowski, who was able to achieve a high one-digit increase in turnover in the last fiscal year. The employees work continually in two shifts in the assembly and printing departments, the capacity utilisation in the mug customising sector is “gigantic”. In France the business is particularly booming – in total more than half of Senator’s turnover is made abroad, the mugs account for around 20% of the overall result. Jeschonowski is also proud of the fact that not one of the approx. 200 workers in Groß-Bieberau and 100 further employees in the sales offices worldwide have a temporary contract – priority is placed on continuity and reliability also with regards to how the employees are treated.

Strict image

Good capacity utilisation in the mug customising area. Overall mugs contribute a fifth towards Senator’s overall turnover.

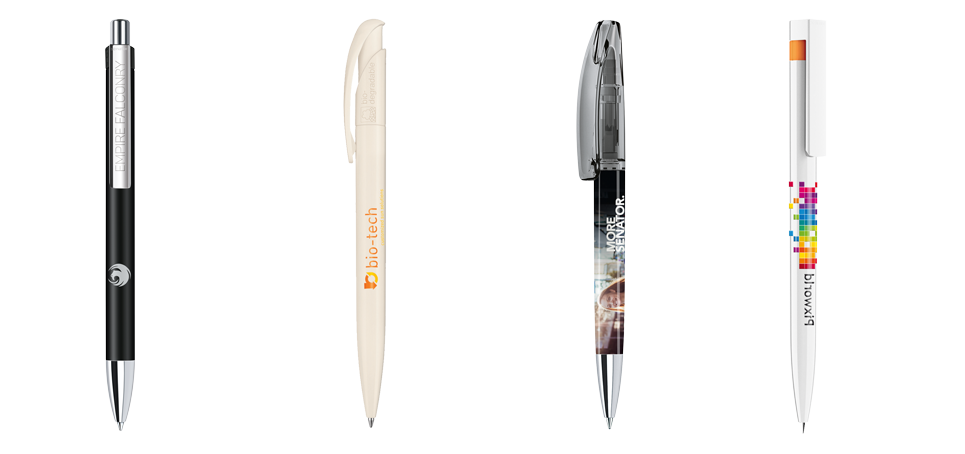

Under the new management Senator has undergone a 180° change in its public image. The diversity of colours that was pushed in the past, but which was rather confusing for many customers and that was ultimately not as easily implementable in the production as originally promised has been replaced by a strict brand management. This has led to good results for the sales figures, catalogue and website. “We have revised the catalogue,” explained Anke Niebel, who in her capacity as Marketing & Communication Manager is responsible for the new design of the publication that is completely produced in-house. “The aim was to increase its readability and yet underline the variety of the options to create individual promotional writing instruments and mugs.” “Internally we always carry out the so-called ‘Grandma test’,” added Jeschonowski. “The contents is only deemed suitable if they are so simple that my grandmother, who is not familiar with the material, can understand them.”

The new catalogue passed the ‘Grandma test’. The diverse models, customising techniques and further services are listed in a clear manner. In spite of the reduction in the spectrum of colours there is still a huge range of possibilities for having CI-compatible models of ballpoints produced. The successful model Liberty alone is offered in 25 different shades, most of the plastic pens offer 15 standard shades per surface and also the white basic models can be combined with ten top colours (on the gripping zone, pusher and tip). The colours of many of the models are freely combinable and companies that need a special corporate colour, can take advantage of Senator’s PMS service. Here, the company from Groß-Bieberau produces the barrel or other parts of the pen in pantone shades in line with the desired requirements. It is guaranteed that the 15 standard colours will remain the same over the next years – which is important for follow-up orders. Everything should remain as uncomplicated as possible for the distributors and their customers. The fast delivery services “5000 in 5” or “Pen Express” are equally market-oriented. In the first case, five models are available that can be delivered within five days after approval of the position sketch in up to five colours for order volumes up to 5,000 pieces. In the scope of the Pen Express service six models can be imprinted in two colours and actually dispatched within two days – here the maximum order quantity is 1,000 pieces per order. The Visual Service that involves Senator producing design drafts of promotional writing instruments and mugs to match the customer’s requirements, is also attractive for distributors.

Made in Germany

The number of novelties has been reduced compared to the past. “We no longer want uncontrolled growth in terms of the models, instead we want to concentrate on the essentials,” said Erik Würkner, Product Management Director. “It is also important that we don’t present the models to the trade until they are ready for market launch. It does us no good to grandly announce something without it being deliverable.” The newcomers include the plastic ballpoint pen, Bridge, that aims to bring new momentum into the advertising sector with strong, rich colours, an elegant design and wide gripping zone and the metal ballpoint, Polar, with its modern-day, linear shape. Both writing instruments, even the one made of metal, are completely “made in Germany”, an aspect that Senator emphasises more and more in its PR work. “We stand behind our local production in Groß-Bieberau,” summed up Jeschonowski, “and want to communicate it correspondingly. ‘Made in Germany‘ is a quality seal that is demanded more and more frequently and which lends us an image that distinguishes us from many of our fellow competitors. So we will continue to invest in machinery and the appropriate employees.” Over 1,000,000 Euros are budgeted for investment for 2018 – investments in better technology, more efficient production methods and of course safety: After all the company wants the number of days without accidents to increase even further.

// Mischa Delbrouck

photos: Mischa Delbrouck (3), © WA Media; Senator (2)