“Brands need brand-name ballpoint pens” – that is the motto of the new campaign of Schneider Schreibgeräte. The traditional company has always relied on “made in Germany” brand quality, a strategy that has brought the company success. Sustainable production methods and economic growth go hand in hand.

The writing instrument specialist launched its new brand concept that combines the effective tradition and viability of the company and accentuates the attributes suitability for everyday use and user friendliness under this claim in the year 2010. The brand strategy is based on four pillars that complement each other and reflect the corporate philosophy: high product quality, humanity, sustainability and the proximity to the users. “Together with our products, the relaunch has contributed towards the achievement of a strong growth in turnover over the last years,” confirmed Frank Groß, Executive Director for the Marketing and Sales Departments. A growth that is something to be proud of: In 2015 a turnover of almost 62 mil. Euros was achieved, which corresponded to around a 55% increase since 2009. Schneider sells its ballpoint pens, fineliners, gel ink pens, highlighters or fountain pens in 130 countries, the export share totals approx. 60%. A strong position that Schneider assumes as one of the leading manufacturers of brand-name ballpoint pens worldwide and which is to be further consolidated by a new campaign. “Brandname instead of no-name” is the motto: The aim is to enable promoting companies to convey special value, instead of presenting any old promotional product.

High product quality

The self-confidence is based on a long tradition and extensive know-how in the field of pen production. Although when Christian Schneider founded the company in the year 1938, he initially produced mechanical turned parts and screws instead of ballpoint pens, when a novel writing instrument came onto the market in Germany after the Second World War, Schneider picked up on the opportunity to invest in a new technology and began to produce and further develop refills for ballpoint pens. The “good Schneider refill” became a synonym for quality in the 1950s and quickly led to Schneider becoming one of the leaders among the refill manufacturers. Already in 1963, the writing capacity of the refills produced in just one day at the factory in Tennenbronn, South Germany, would have covered the distance up to the moon. Christian Schneider’s son, Roland Schneider, took over the company in 1978. Thanks to his innovative drive and forward planning, Schneider excelled over the following decades with decisive developments and successively expanded the production to include a full range of writing instruments.

Martina Schneider, the granddaughter of the company founder, Christian Schneider, proudly presenting the new promotion campaign.

The Viscoglide® technology that was introduced in 2005 and which combines the writing feeling of gel pens and the durability and capacity of ballpoint pens, was revolutionary. Thanks to the “plug+play system”, which Schneider offers for most of its ballpoint pens, the newly developed Viscoglide® refills are available for almost all models in the retail and promotion sector. Christian Schneider has also inherited the innovative spirit of the family. A member of the company’s management since 2010, together with his father Roland Schneider and the co-Managing Director Frank Groß, the founder’s grandson is further pushing the development of the writing instrument specialist. The focus here still lies on the “good Schneider refill”, which continues to be a synonym for meticulous production. The appreciation for “made in Germany” quality obviously pays off: 570 people are employed in total in the locations Tennenbronn, Wernigerode (fountain pen production) and Weilheim (headquarters of Schneider Novus Vertriebs GmbH). Producing around 2.7 mil. writing instruments a day, in the meantime the writing capacity would cover the distance to the planet Pluto, which is almost 5 billion km away. In spite of the impressive size of the family company, social subjects never fall by the wayside at Schneider. The company founder, Christian Schneider, already relied on personal contacts and a good work climate: Company outings, incentive bonuses and profit-sharing already belonged to the company’s philosophy in the 1960s. In the same way, comprehensive employee loyalty measures ensure important specialised knowledge on-site. Plenty of which has been gained over the past decades, because the average serving time of the employees is 17 years. “All production steps from the development of the prototypes, to the production, through to the quality management are bundled at the headquarters and each of the employees is an expert in his own field,” explained Martina Schneider, granddaughter of the company founder and Marketing Manager at Schneider. “All of our employees are fully committed,” commented Klaus Broghammer, who himself has been working for the firm for 33 years – he spent 17 of them as the Sales Director for the Promotional Products Department.

Sustainability

Through their close ties to the region an environmental- friendly attitude that is deeply rooted within the organisation has arisen over the years, which plays into the hands of today’s trend towards sustainability. The sustainability principle was officially anchored into the corporate strategy in 1998 after Schneider became EMAS certified – an EU ecological audit that in the form of a joint system between environmental management and an environmental audit was designed to lead to the continual improvement of the company’s environmental performance. The continual improvement process is manifested in a public environmental declaration and the set goals are examined in a re-evaluation process every three years. The comprehensive recycling of product components, energy derived 100% from water power and renewable energies, the avoidance of using PVC in the production and the reduction of emissions and waste are just part of the farreaching measures that Schneider implements. For example, thanks to renovations and energyefficient measures – such as a photovoltaic system and a combined heat and power plant for the generation of energy and heat – 50% of the heating energy is saved at the headquarters in spite of there being an additional building there now. In addition to a staff bus, an ebike campaign also contributes to the good (working) climate. “We sponsor ebikes for employees, who travel to work without their car at least 80 days a year and who want to travel by bike instead. We have sponsored over 60 ebikes in the meantime and our employees travelled 160,000 km on their ebikes instead of by car in 2015 alone – a measure that has a threefold effect: as an incentive, as a healthmaintaining measure and for the good of the environment,” concluded Martina Schneider.

Proximity to the user

The Executive Director Frank Groß (l.) and the Sales Director of the Promotional Product Department, Klaus Broghammer.

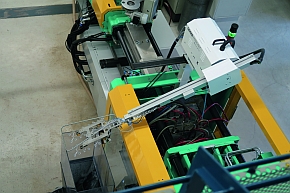

The right refill for every ballpoint pen and the right writing instrument for everyone – these have been the principles of the writing instrument specialist from the Black Forest since it started producing ballpoint pens. As such, the priority of the product range always lies on suitability for everyday use and user-friendliness. A high vertical range of manufacture enables optimal flexibility, because from the tool and mould-making, to the refill production, plastic die-casting department, assembly, packing, screen and pad-printing and special machine construction, all areas are united under one roof. The “Pen Configurator” – an intuitively designed online tool that enables the fast and simple selection of the appropriate promotional writing instrument is customer-friendly for both the promotional products trade and for the industry customers. The industry customers can forward on the PDF that they have created using the tool to their preferred distributors and request corresponding quotes, because distributor loyalty is a further fundamental principle at Schneider.

Brand for brands

The express model Like made out of opaque or transparent plastic is individually combinable in 22 colours. Delivery takes place within six working days after approval of the proofs.

Schneider has achieved a positive external effect with its products and corporate philosophy, which in turn has a positive impact on the image of the companies that advertise using Schneider writing instruments. The new campaign in the promotion sector builds on this external image: “Brands need brand-name ballpoint pens“. The established brand Schneider should be the first choice for companies that want to convey a strong brand image themselves. Keywords like “Germany’s no. 1” (as the manufacturer of brand ballpoint pens according to Panelmarkt), “Quality”, “Made in Germany” or “Tradition and Experience” play a decisive role here. “We offer our distributors optimal opportunities to carry the new brand strategy to the outside world in the form of a wide selection of marketing materials and thus also profit from it themselves. Thanks to a greater demand for branded writing instruments, they become more independent from goods from the Far East themselves and score highly in the contract awarding process when their product line-up includes a brand-name writing instrument. Our writing instruments excel as a result of their discrete high recognition value. This enables the focus to be ideally placed on the brands, while at the same time a sense of high value is conveyed to the recipient through the established brand.” Schneider offers the right branded ballpoint for every possible area of application – from the popular model K15, to the Like that can be delivered within 6 days as an express model, through to innovative novelties with a superior appearance and stylus cap, such as the Epsilon Touch. Furthermore, expanding the main factory in Tennenbronn will ensure the future development: “The warehouse, dispatch and packing activities will be carried out in new factory halls from 2017 onwards, which are located just two kilometres away from the headquarters,” reported Groß. “This enables the production in Factory I to be further expanded to accommodate the growth of the past years.” The promotion division is to account for a large share of this future growth. The new campaign is allowing the creative minds of the writing instrument melting pot in the Black Forest to remain optimistic that these goals will be achieved in the future.